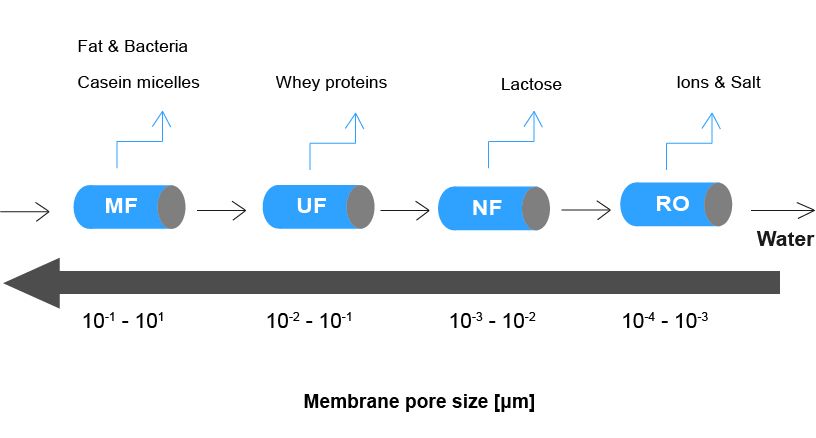

MEMBRANE FILTRATION TECHNOLOGY FOR DAIRY

Microfiltration (MF)

Microfiltration is a process which selectively separates particles with a molecular weight greater than 0.1 micron (which corresponds to ca. 500,000 Da). It separates mainly suspended solids, bacteria, macroorganisms, and micelles. However, soluble molecules are not retained by MF membranes. In the Dairy Industry, Microfiltration is applied to the removal of bacteria and the separation of casein micelles and soluble proteins.

Ultrafiltration (UF)

On top of what MF membranes can achieve, UF membranes are able to remove macromolecules such as lipids and proteins. UF membranes are usually classified as having a pore size between 1000 to 500,000 Da. In the Dairy Industry, Ultrafiltration is applied to standardisation and concentration of milk proteins and solids, and whole milk processing reducing the skimmed milk fat content.

Nanofiltration (NF)

Nanofiltration, also known as loose-Reverse Osmosis, falls between Reverse Osmosis and Ultrafiltration. It separates low molecular weight compounds (above 200 and 1,000 Da) from larger molecules. NF membranes can remove also smaller molecules (micro-molecules) such as sugars and divalent salts. In the Dairy Industry, Nanofiltration is applied to the partial demineralisation of whey and the production of lactose-free milk.

Reverse Osmosis (RO)

Reverse Osmosis is a dewatering process which operates at high pressure and is based on a very dense membrane. Reverse Osmosis membranes separate solutes with a molecular weight of ca. 200 Da and above and exhibit ≥ 80% NaCl retention rejection. Thus, they can remove monovalent salts as well, being used when desalination or complete salts retention is required. In the Dairy Industry, Reverse Osmosis is mainly applied to the concentration of whey.

MAIN APPLICATIONS

Whey protein clarification & concentration

Whey is a liquid by-product of the dairy industry that is created during the production of cheese and casein. Because of the functional and nutritional qualities of its proteins, it has several applications in food technology as a raw material.

In the Dairy Industry, membrane technology, particularly Ultrafiltration (UF), has been utilised to manufacture whey protein concentrates (WPC) because it allows for the selective concentration of proteins in proportion to other components.

Preconcentration of milk for cheesemaking

The ability to use Ultrafiltration to preconcentrate milk before cheese making has been extensively exploited for a wide variety of cheeses. By this procedure, milk is concentrated at the desired level by keeping constant the whey proteins to casein ratio.

Protein-standardised milk

The protein amount of milk collected by dairy plants varies by season due to a variety of factors including stage of lactation, weather, feeding and breed of lactating cows. This issue is eliminated by a modest increase in protein content by Ultrafiltration (UF). In many cheese plants, especially those that use highly mechanised equipment, the protein level of cheese milk is increased to 3.7-4.5 % throughout the year, regardless of the aforementioned factors.

Lactose concentration

For lactose concentration and partial demineralisation, Nanofiltration (NF) is commonly utilised in the Dairy Industry. Lactose-free milk or whey volume can be further lowered by allowing monovalent ions to flow through while partially rejecting multivalent ions, in order to attain savings in transportation costs.

Bacteria removal

Like most food, milk and its derivatives provide a favourable environment for spoilage microorganisms. Consequently, pre-treatment as well as temperature-time parameters must be selected in order to control microbial growth. This applies to the production of cheese milk, to the preparation of milk powder and to the production of Extended Shelf Life (ESL) milk. The membrane pore size is selected to retain bacteria and spores, allowing all other non-fat milk components to pass.

Milk concentrates and isolates

Membrane filtration technology is used to obtain milk protein concentrates and isolates from skimmed milk. Whole milk is divided into skimmed milk and cream, and then the skimmed milk is fractionated using Ultrafiltration membranes to concentrate the milk proteins even further.

Dairy processing brochure

OUR MEMBRANE SOLUTIONS

How can we help you?

Do not hesitate to contact our experts who will work with you to conduct project assessments, run a pilot test, customise, design and install your membrane filtration system, which best fits your needs.

The membrane selection will depend on your specific application type and target. We recommend using either our spiral-wound or tubular membranes for dairy applications. At the same time, we offer all the various membrane filtration process: microfiltration, ultrafiltration, nanofiltration, and reverse osmosis.

Spiral-Wound Membrane Elements

- FG – SpiraCore® – Dairy UF-5K-10K for enzymes, dairy, drinking water, and protein removal.

- FG – SpiraCore® – Dairy NF1 Membrane Series for whey desalination.

- FG – SpiraCore® – Dairy NF2 Membrane Series for lactose removal.

- FG – SpiraCore® – Dairy RO4 Membrane Series for dairy concentrate.

- FG – SpiraCore® – RO Polisher Membrane Series for recovery of evaporator condensate and UF/NF permeate.

- FG – SpiraCore®-Dairy HWS – NF Membrane Series and FG – SpiraCore®-Dairy HWS – RO Membrane Series for production of sanitary water for Dairy and Food production processes.

Tubular Membranes

- AFC30 & AFC40 Nanofiltration Membranes for lactose or mineral removal/concentration.

- AFC-99 Membranes for Whey Protein Concentration (WPC).

- ES625 MEMBRANES for skim or whole milk purification.

- ESP04 MEMBRANES for RecoCIP process caustic recovery dairy waste washings.