B1 Series Tubular Membrane Modules

B1 Series Tubular Membrane Modules

The B1 module provides a robust proven housing for Ultrafiltration, Nanofiltration and Reverse Osmosis and can be fitted with a wide range of fully interchangeable membrane elements.

The open channel, highly turbulent flow design allows a wide variety of fluids to be processed, with minimal pre-treatment and permits easy replacement of membranes by the user. The design is also free of dead spaces reducing the fouling potential of the membranes while ensuring maximum effectiveness of cleaning-in-place procedures.

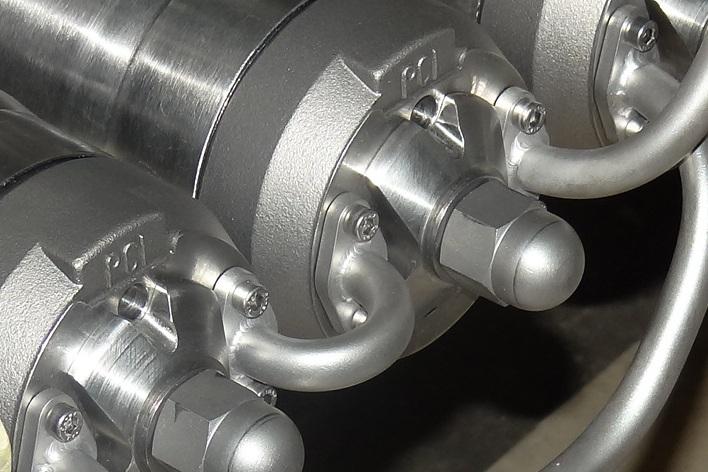

The module is of stainless steel construction, with the 12.7mm diameter tubular membranes fitted into 18 perforated support tubes. Different end caps are available to connect varying numbers of the tubes in series or parallel flow, to allow operation at different flow rates to suit crossflow and pressure drop requirements for individual applications.

Due to the robust design, the module can be used in systems designed for operation at up to 80 bar at 80°C, dependent on the type of membrane fitted. The module is available as standard in 3.66m, 2.4m and 1.2m lengths, providing membrane areas of 2.6m2, 1.7m2 and 0.9m2 respectively.

Flow of the process fluid through the tubes is effected by specially designed end-caps whose design varies depending on the process requirements – Series Flow, Twin Entry Flow, Parallel Flow.

Key features and benefits

- Stainless steel construction – robust and inert to most chemicals

- Open channel, tubular design – minimal feed prefiltration required; suitable for high levels of colloids and suspended solids: maximum effectiveness of CIP

- Choice of flow path through module – optimum cross-flow velocities to minimise fouling with acceptable pressure drop

- Proven membranes – with application in the food, beverage, chemical, wastewater and pharmaceutical industries

- Compact module design – quick and easy plant construction

Series Flow (RO) Arrangement

For reverse osmosis systems the “series flow” module has channels molded in the end-caps connecting all the 18 tubes in series.

Twin Entry (UF) Arrangement

For viscous materials an alternative end-cap type (known as “twin” or “double-entry”) is used which provides two parallel channels each of nine tubes in series.

Parallel Flow (UF) Arrangement

The parallel end-caps allow all 18 tubes to operate in parallel allowing the highest crossflow velocities to be used with acceptable pressure drop. For less viscous materials the parallel end caps arrangement results in lower energy consumption