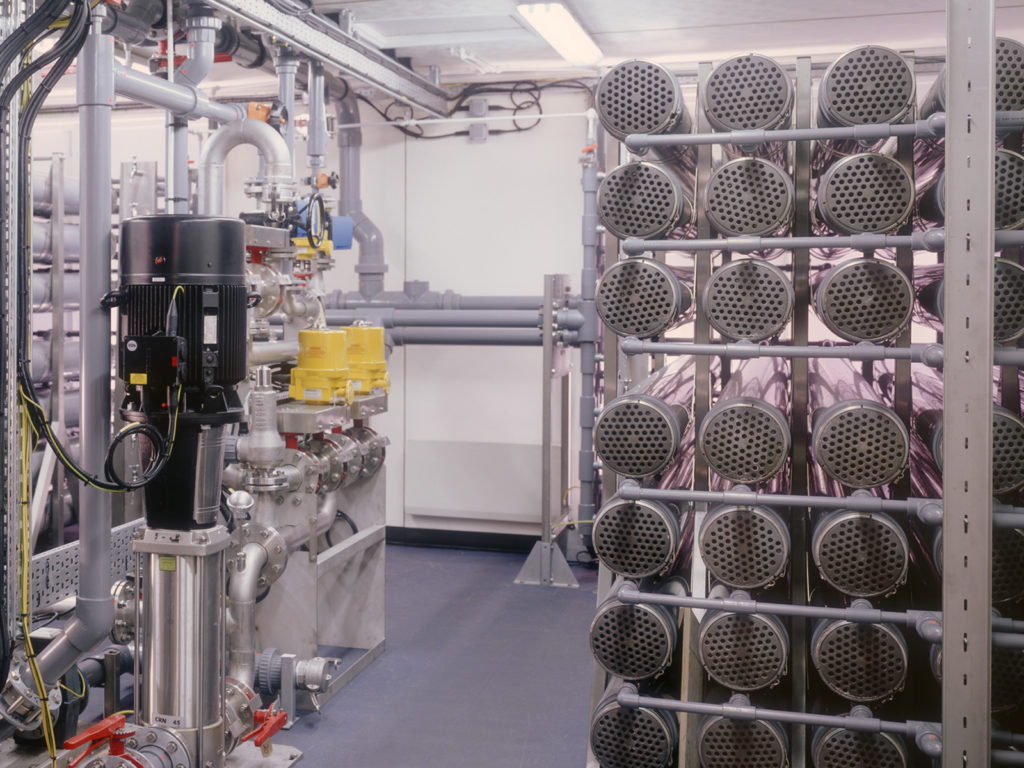

Membrane Filtration Plants

After the preliminary assessment and successful pilot trial, the next step is the realisation of the full-scale plant. Our approach provides the highest possible scale-up security due to vast experience and working on real data received from pilot trials.

Membrane filtration systems are the heart of many separation processes. Application R&D, equipment design, and manufacturing quality are all important aspects of the project’s overall success. To start, the correct membrane configuration must be selected. There are many formats to choose from, including tubular, hollow fiber and spiral-wound membranes. Then, the most suitable membrane materials and operating parameters need to be selected. At last, the choices must be validated through a sustainable membrane cleaning and replacement programme.

Membrane Filtration Stack Examples

A19 stack

C10 stack

B1 stack

Custom Membrane Filtration Systems

As well as offering a complete portfolio of membrane solutions for your industrial processes, we provide tailor-made industrial filtration systems which guarantee optimal performance for your specific application. During the design phase of your membrane system, PCI Membranes’ engineers will work with you to perform pilot tests, and ensure the optimal design, sizing and configuration of the full-scale filtration system. Together, we can build a fully customised system which is truly suitable for your application, no matter how unique it may be.