Membrane Filtration for Soy Sauce Production

The clarification is a crucial step of soy sauce production. The aim is to make the soy sauce clear while keeping its vitamins, minerals, proteins and antioxidants and ensuring proper shelf-life. PCI Membranes offer spiral-wound membrane solutions that protects the nutriments while limiting the addition of preservatives. In addition, the quality and tracebility of our products allow us to ensure constant and reliable performance.

Soy sauce clarification

As a traditional fermented food in eastern Asia, soy sauce has become a widely used seasoning across the world. Soy sauce is made from soybean and wheat through a complex fermentation processes involving enzymatic catalysis by various microorganisms. With time, saccharides, amino acid nitrogen, organic acids, and other constituents that compose the soy sauce will give it a unique flavor.

After brewing for several months, raw soy sauce contains large amounts of fermented mash, which is usually filterpressed to remove the extra suspended solids; then, a final refinement is required to stabilise its flavor and color. Ultrafiltration membranes will refine the filter-pressed soy sauce by stopping the microbial and enzymatic reaction. This final step before bottling will clarify the sauce while maintaining the organoleptic properties and nutritional elements of the soy sauce. It will also enable the removal of microorganisms, which will stop the fermentation process and stabilise the soy sauce to ensure long shelf life.

Traditional methods for the production of soy sauce imply several batch operations that are labour- and time-consuming. Moreover, those methods can not remove microorganisms and bacteria, which limit the product’s expiration time. Using spiral-wound membranes brings several advantages: getting high clarification, keeping good flavor and nutrients, retaining soluble proteins as well as ensuring a small degree of browning. Furthermore, it is cost effective and requires low maintenance.

The soy sauce clarification process in details

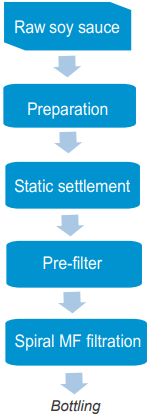

The production of soy sauce is divided into 4 major steps: raw soy sauce preparation, static settling, pre-filtration and microfiltration using spiral-wound membrane elements, as well as a number of sub-steps.

• During the static settling, the fermentation of the soy sauce develops large amounts of fermented mash and suspended solids that will need to be pre-filtered.

• The microfiltration step using spiral-wound membranes with a molecular weight cut-off (MWCO) of 500,000 Da, will remove macro-molecular proteins, and organic matter as well as colloids while improving the clarity of the sauce. The membranes used for this step also remove bacteria and microorganisms, ensuring long shelf life. For this application, we recommend using our FG-SpiraCore MF500 spiral-wound membrane elements.

The spiral wound membrane technology

How the spiral wound module works:

Spiral-wound membrane elements consist of a feed spacer, two membrane sheets, and a permeate spacer.

The feed solution is supplied to the feed side of the module, entering the feed spacers. The purified water crosses the membrane sheets, is collected within the permeate spacers and, following a spiral pattern, leaves the element through the central collection tube. The remaining feed solution passes through the elements and leaves from the opposite end of the module. A spiral-wound membrane module consists of one or more elements in series.

The advantages of using PCI Microfiltration Spiral Wound Membranes Elements

Used for soy sauce microfiltration applications, PCI Membranes’ FG-SPIRACORE MF500 spiral-wound membrane elements are made of PVDF material with a MWCO of 500,000 Da. The major advantage of using this material is its good chemical resistance, which ensures a wide pH range (2-11), and high chlorine tolerance.

Within the FG-SpiraCore EXC-So-MF line of spiral-wound membrane elements are several feed spacer thicknesses available. Do not hesitate to ask your PCI Membranes contact for more details.