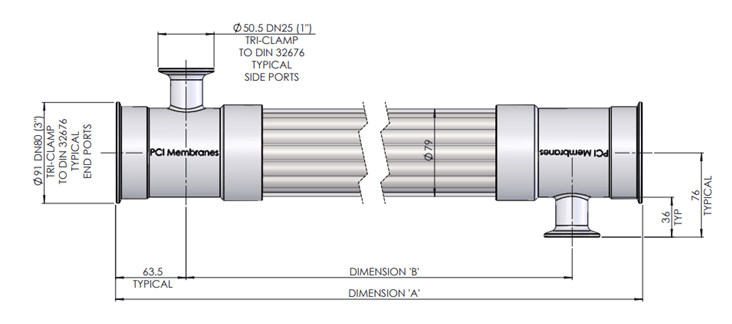

K19 Series Tubular Membrane Modules

The K19 membrane system from PCI Membranes is purpose-built for juice applications, delivering exceptional yield, reliability, and return on investment — all without the need for expensive equipment upgrades.

Benefits

- High product yield: Delivers 90–95% product recovery for greater efficiency.

- Robust performance: Proven reliability in rigorous field trials, with no reported failures under typical operating conditions.

- High-pressure capability: Operates at pressures up to 7 Bar to handle demanding applications.

- Food-safe design: Meets strict Food Contact Compliance (FCC) standards, featuring BPA-free housing that’s safer for human consumption and more environmentally friendly.

- Reduced downtime: Single-use format speeds up change-outs and minimizes cleaning, lowering reliance on chemicals.

- Enhanced visibility: Integrated see-through window lets operators monitor fluid flow and check membrane function in real time.

The K19 Series from PCI Membranes is a high-performance, tubular membrane filtration system engineered specifically for efficient juice clarification across a wide range of fruit and vegetable juices. Designed for industrial juice processing, the K19 delivers consistent, high-solids filtration and is available in multiple module lengths to meet the operational demands of juice production facilities. For processors looking to upgrade or retrofit existing filtration systems, compact K19 modules offer a cost-effective replacement solution, ensuring improved juice yield, clarity, and processing efficiency.

The membranes are fitted in a BPA free housing.

Application

The K19 Series is engineered to deliver an alternative to the standard A19 with a stainless steel housing and both offering an efficient juice clarification process for a wide range of juice varieties. K19 modules are available with a wide range of membranes with different pore sizes for light or dark juice filtration, ensuring that larger particles and turbidity are retained, while color, flavor and aroma pass through to the filtrate side. K19 is ideal to clarify a diverse range of juices, including orange, apple, pear, cranberry, grape, berries, carrots, açai, pomegranate and other exotic varieties.

Advantages

1. Enhanced environmental sustainability and efficiency through the use of BPA-free materials.

K19 is designed with a BPA free housing material. BPA is known to be a harmful chemical that can leach into food and beverages, posing health risks such as hormonal disruptions and increased risk of certain cancers. BPA-free materials eliminate this risk, ensuring safer consumption of processed juice. BPA-free membranes often incorporate advanced materials and technologies that can improve the efficiency and effectiveness of the juice processing, such as better filtration and longevity of the membranes.

2. Robust construction

Because of their robust construction, you will not encounter problems of membrane tube explosion, which can be an issue with other membrane manufacturers with over 12% greater pressure rating.

3. Tailored PVDF membrane types for Fruit/Vegetable Juices

A summary of the main membranes used for juice clarification is shown below.

| Membrane | Specification | Nominal retention character |

| FPU10 | Ultrafiltration | 100 kDa |

| FPU20 | Ultrafiltration | 200 kDa |

| LPU450 | Ultrafiltration | 450 kDa |

| LMU02 | Microfiltration | 0.2 µm |

For apple juices only, we recommend using our FPU10 tubular UF membranes with a MWCO (Molecular Weight Cut-Off) of 100 kDa. This will help to achieve very light colour of clarified apple juice while maintaining a good quality product, with low turbidity up to a maximum of 0.5 NTU.

The most common UF membrane used in juice applications has a MWCO of 200 kDa. When processing light juices, we recommend using our FPU20 tubular ultrafiltration membranes.

For flexibility, when running both light and pink juices, LPU450 tubular UF membranes with a MWCO of 400-500 kDa can be used. These membranes offer greater performance with a minimum pressure drop, while maintaining the organoleptic characteristics of the juices.

For dark juices, we recommend using our LMU02 tubular MF membranes with a nominal pore size of 0.2 µm. They have a more opened membrane surface compared to the LPU450 membranes. This will help keep the colour while maintaining a good quality product, with low turbidity.

Membrane selection guideline:

| Juice Classification | Membrane Type | Advantages | Remarks |

| Light: Apple only | FPU10 | High quality product and low turbidity maximum of 0.5 NTU | Only recommended for apple juice |

| Light | FPU20 | High quality product and turbidity lower than 1 NTU | It offers flexibility in terms of production scheduling when using different types of juices |

| Pink | LPU450 | High quality product and turbidity lower than 1 NTU | Guarantee an intensive colour of the clarified juice |

| Dark | LMU02 | High quality product and low turbidity | Not suitable for Apple or any light coloured juices |

4. Significant cost savings

Increased Recovery Rates & Yields

Higher operating pressures facilitate improved recovery rates, achieving 90% to 95% recovery subject to solids level. This means more juice is produced per batch, leading to greater financial returns. Though exact monetary values for recovered juice are not provided, the increase in yield is evident in the increased number of litres; can or cartons generated from the same batch of raw juice.

Cost-Effective Transition

For companies restricted in CAPEX for upgrading to A19/Stainless Steel options, the K19 offers a viable OPEX solution. Transitioning to higher pressures with K19 does not require significant capital expenditure, making it an efficient upgrade path.

Reduced Downtime and Labor Costs

Are you tired of costly interruptions? Our competitor’s membranes average 90 minutes of downtime per incident, costing valuable time and material to repair the system, leading to significant financial losses. In extensive trials, our K19 membranes showed zero issues, ensuring seamless operations and maximizing productivity. Transform your operations today!

5. Customisation and Flow Control

The K19 product allows for precise control over permeate flow. By selecting appropriately sized gaskets and cross flow volume, the Applications team can optimise system performance. PCI permeate gaskets, enhance crossflow volume in the latter modules, contributing to improved system efficiency.

Datasheet

| K19 datasheet | Download |