The consumption of fruit juices has significantly increased during last years and it is growing remarkably, since consumers are interested in healthy products which are practical and ready to be consumed. To produce juices, safety and quality improvement, nutritional value, product and process cost minimisation are fundamental aspects.

Traditional methods for the production of single strength or concentrated juices involve several batch operations that are labor- and time-consuming. Moreover, those methods can’t remove microorganisms and bacteria, which limits the product’s expiration time. Using tubular membrane brings several advantages: getting high clarification, keeping good flavor and nutriments, ensuring good maintenance of vitamin C, retaining soluble proteins as well as achieving small degree of browning. Furthermore, it is cost effective and requires low maintenance.

Why should you trust us as your new membranes provider?

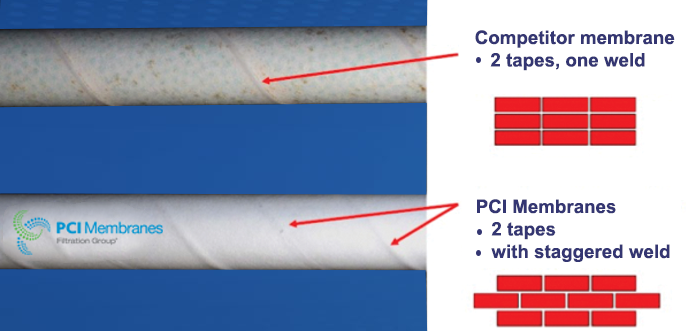

① Robust construction

Our double-ply membrane tubes & SS AISI 316L housings allow operating temperatures up to 60°C and operating pressures up to 7 bar.

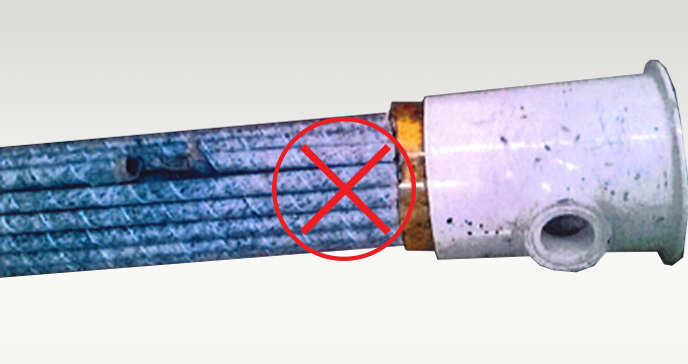

② No problems with membrane tube explosion

Because of their robust construction, you will not encounter problems of membrane tube explosion, which can be an issue with other membrane manufacturers.

③ Tailored PVDF membrane types for Fruit/Vegetable Juices

- Light-coloured juices: FPA10/FPS10 (100 kDa MWCO) and FPA20/FPS20 (200 kDa MWCO)

- Pink-coloured juices: LPA450/LPS450 (450 kDa MWCO)

- Dark-colored juices: LMA02/LMS02 (0.2 µm pore size)

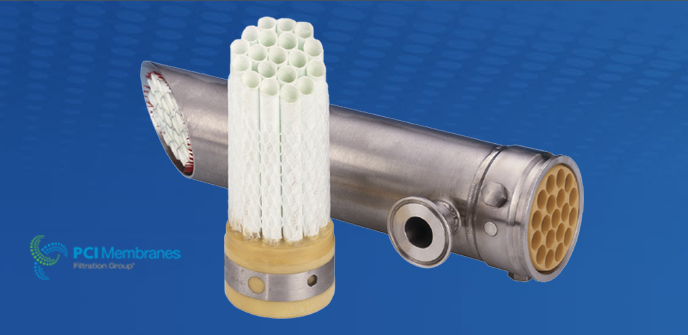

④ Significant cost savings

You will be able to save your costs, thanks to our innovative recoreable design for simple & rapid membrane replacement. When put into operation, you just need to replace the membrane core instead of the whole module.

The advantages of our membranes

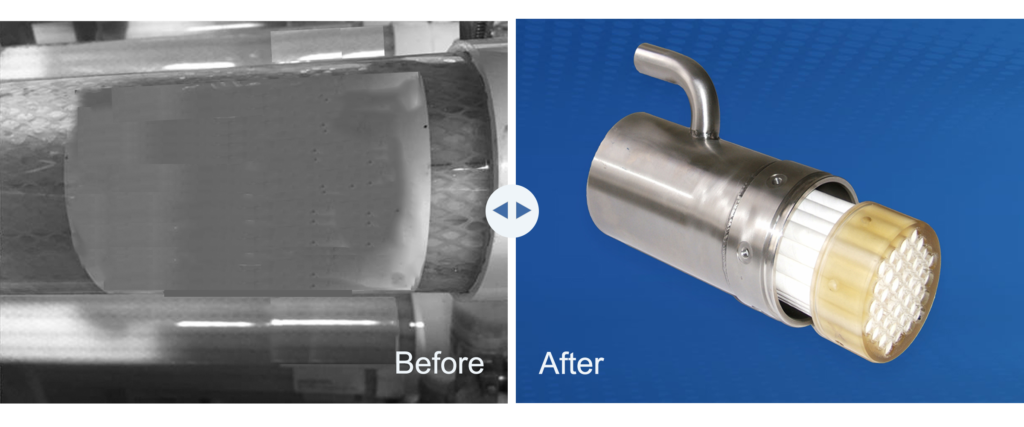

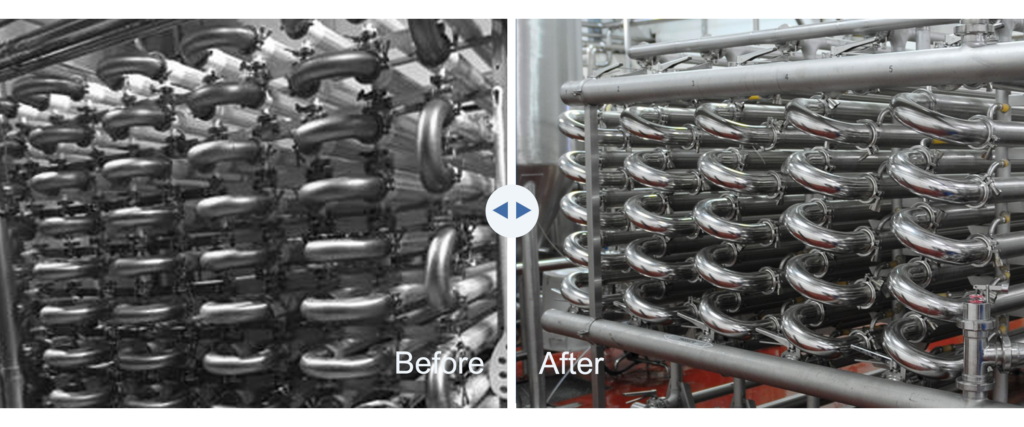

Before vs. After

✓ Minimum adjustments to the existing UF/MF systems are required during transition to a robust & cost effective membrane core in stainless steel housing;

✓ It is easy to check the clarified juice’s quality from the transparent hoses connecting the housing’s permeate offtakes to the manifold;

✓ It is possible to reduce the number of installed modules per pathway from 14 to 12 pieces, without reducing the throughput of the UF system;

✓ Less maintenance and process downtime due to the robust construction of PCI Membranes’ products, which allows a maximum operating temperature and pressure of 60°C and 7 bar respectively;

✓ Reduced OpEx and environmental impact as the only replaced element is a membrane core while the stainless steel housing can be reused.

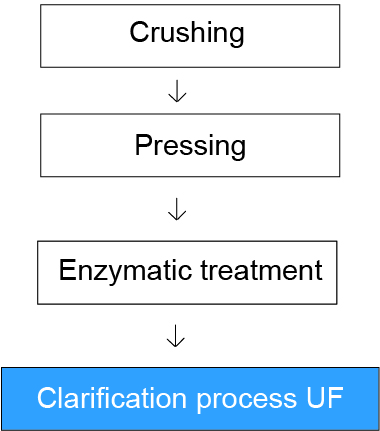

The fruit juice clarification process in details

The fruit juice clarification process in details

The production of juices is divided into 4 major steps: crushing, pressing, enzymatic treatment and clarification/filtration by membranes, as well as a number of sub-steps.

• During the crushing and pressing of the fruit, the solubilisation of pectins and starches takes place, which has to be depectinised and destarched before the microfiltration/ultrafiltration process step.

• The depectinisation process is done by adding synthetic or natural enzymes. It is one of the most important factors – together with the quality/type and quantity of activated carbon or bentonite added to the process – that influence the membranes’ filtration capacity.

• The most recent method for juice filtration is the use of microfiltration (MF) or ultrafiltration (UF) membrane process. Membranes used for this application are working in batch or topped batch mode with depectinised juice. Typical juice characteristic is: 9 – 12oBrix, pH 2 -4 and initial pulp content of about 2%. Diafiltration step is often used to increase yield (concentrate only).

How to choose the right module and membranes for juice processing?

Choosing the right module

For UF and MF tubular membranes to be used in fruit juices applications, we recommend using either the A19 or A37 module. They both are comprised of a robust stainless steel housing and a replaceable core of 19 or 37 tubular membranes, respectively. They are manufactured with materials approved by the FDA and EU regulations. The open channel design of the A19 and A37 modules enables them to treat liquids with high suspended solids, without plugging and ensuring highly effective CIP process. Our unique in-situ replaceable core feature enables fast, easy and cost-effective remembraning operations.

Choosing the right membrane

For only apple juices, we recommend using our FPA10 or FPS10 tubular ultrafiltration (UF) membranes (depending on the modules’ configuration) with a nominal separation of 100 000 MWCO (Molecular Weight Cut-Off). This will help to achieve very light colour of apple juice while maintaining a good quality product, with low turbidity up to a maximum of 0.5 NTU.

• The most common UF membrane used in juice applications has a nominal separation of 200 000 MWCO (Molecular Weight Cut-Off) and are made with PVDF material. For the light juices ultrafiltration process (apples, pears, light grapes and others), we recommend using our FPA20 or FPS20 tubular ultrafiltration membranes (depending on the modules’ configuration).

• For flexibility, when running multiple pink juices (do not apply to apple juices) LPA450 or LPS450 tubular (UF) ultrafiltration membranes made of PVDF and having of 400K-500K MWCO (Molecular Weight Cut-Off) can be used. These membrane offers greater performance with a minimum pressure drop, while maintaining the organoleptic characteristics of the treated pink juices.

• For dark juices (beetroot, pomegranate, cherry and others), we recommend using our LMA02 or LMS02 tubular microfiltration (MF) membranes (depending on the modules’ configuration) with a nominal separation of 0.2 micron. They have a more opened membrane surface compared to the FPA20 and FPS20 membranes and are made of PVDF material. This will help keep the colour while maintaining a good quality product, with low turbidity up to a maximum of 1 NTU.

• We also offer a 6, 8, 12.5 mm (in a B1 module) tube diameter membrane for fluids with solid with MWCOs ranging from 20 000 Daltons cut off point to 0.2 micron separation point to cover all needs, including aggressive fluids like lemon and lime juices.

How can we help you?

If you are ready to increase the robustness of your UF unit and start saving money today, contact our experts. They will work with you in calculating the return of investment of PCI Membranes’ solution, and guide you through the steps of replacing your existing membrane and modules.