Articles

Design of MBR Plants

Learn how to design of MBR plants, advancing your wastewater treatment processes with improved performance and cost-effectiveness.

Milk Standardisation – Membrane solutions for dairy products

Standardisation refers to the process of adjusting the fat, protein, solids and non-fat content of milk and cream to standardise values, depending on the type of end-product being produced.

Membrane Bioreactors (MBR) for Wastewater Treatment

A Membrane BioReactor (MBR) is a process which combines a microfiltration or ultrafiltration membrane unit with a suspended growth bioreactor, and is now widely used in both municipal and industrial WasteWater Treatment Plants (WWTPs).

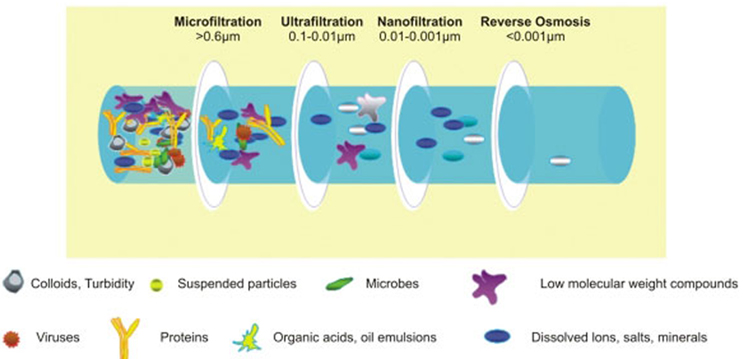

Potable water treatment

To ensure potable water meets the required standard, it’s essential that the water goes through appropriate treatment before delivery. Membrane filtration is an important stage in potable water treatment. The aim of a membrane filtration system is to remove unwanted substances from water using microfiltration, ultrafiltration, nanofiltration, or reverse osmosis.

Choosing the Right Membrane

Choosing the right membrane for each application is vital and membrane filtration specialists such as PCI Membranes can help engineers make the right decision.

Concentration of grape must by reverse osmosis

Tubular reverse osmosis is a process well-suited for the concentration of grape must prior to vinification, since no pretreatment is required, and very high product quality is realised at economical cost.

Dyestuff & Digital Ink Processing

Tubular membrane technology is the BAT (Best Available Technology) in the dyestuffs industry, in particular for reactive, acid and direct dyes, as a way of producing high quality products, maximising yields and capacity, and saving raw materials. Tubular nanofiltration membranes are used for two purposes: desalting and concentration.

Evaporator Condensate Recovery

Evaporators are used extensively in the food, dairy, and distillation industries as a method of removing water from a fluid to obtain a more stable or reduced volume product, often by subsequently drying the concentrate to a powder.

Principles of Membrane Technology (Pressure-driven processes)

A membrane can be defined as an interface between two phases

Single Stage Treatment of Landfill Leachate

PCI Membranes offers state-of-the-art membrane technology for leachate treatment, which is often used as part of the overall treatment system to meet the requirements of individual landfill sites.

The Fyne Process

PCI Membranes’ own 12mm diameter tubular membranes are used in the Fyne process due to their ability to handle suspended solids without blocking of membrane pores.

Water Recovery in the Textile Industry

Large amounts of process water are used in the textile industry throughout the world.

Tubular Microfiltration Membranes For Clarification Of Juices

Karolina Pokus, MSc. Chemical & Process Eng. Application Engineer. ; 04/08/18

PCI Membranes filtration membrane technology for the juice industry was developed about 30 years ago and has been incorporated as a new method to replace rotary vacuum drum filters. This method helps in the production of juice concentration with very reliable clarity and cost-effective production savings.