Membrane Bioreactors (MBR) for Wastewater Treatment

Executive summary

- The Membrane Bioreactor (MBR) couples an activated sludge reactor with a membrane filtration unit;

- MBR is a very efficient treatment with several advantages over conventional activated sludge technologies;

- MBR is used for both municipal and industrial wastewater treatment applications;

- Two MBR configurations are available (submerged and sidestream). PCI Membranes can help you choosing the proper solution for your plant as we are one of the few suppliers offering both.

What is a membrane bioreactor?

A Membrane BioReactor (MBR) is a process which combines a microfiltration or ultrafiltration membrane unit with a suspended growth bioreactor, and is now widely used in both municipal and industrial WasteWater Treatment Plants (WWTPs).

1) Bioreactor:

In a wastewater treatment process, a bioreactor is specifically-designed chamber to support a biologically active environment, namely where bacteria and protozoa (the so-called biomass) can grow and consume some (or all) the substances within the raw wastewater.

They can be aerobic (to remove organic matter and oxidize ammonia to nitrate), anoxic (to remove nitrogen from nitrates to nitrogen gas) or anaerobic (to remove organic matter), depending on the presence of oxygen and nitrates or their absence. Typically, membranes are installed after aerobic or anaerobic bioreactors (respectively, the MBR and the An MBR processes).

There are three types of bioreactors:

- Suspended growth bioreactors, where the biomass grows into flocs;

- Attached growth (or biofilm) bioreactors, where the biomass grows attached to carriers;

- Hybrid bioreactors, which combines suspended and attached growth.

Typically, suspended growth bioreactors are these ones used for MBR processes. If properly designed, hybrid bioreactors can be used as well.

2) Membranes:

In the MBR process, membranes act as a solid-liquid separation device, keeping the biomass within the bioreactor before discharging the treated effluent to the nature. Basically, they take the place of clarifiers used in the conventional activated sludge (CAS) process.

Both micro- (MF) and ultrafiltration (UF) membranes can be used in MBR applications. Typically, UF membranes are the preferred choice because of their superior separation characteristics (thus, being able to remove some colloids and viruses as well) and lower fouling tendency (because of the smaller pore size, they have a lower risk of pore clogging).

There are three types of membrane geometries used for MBRs:

- Hollow fibre (HF);

- Flat sheet (FS);

- Tubular (or multi-tubular, MT).

Other configurations, such as spiral-wound (SW), are not suitable to MBR applications because of their sensitivity to suspended solids contents.

How does a membrane bioreactor work in wastewater treatment processes?

The crucial function of membranes is to separate solids from a liquid. In activated sludge facilities, this is traditionally accomplished using secondary clarifiers.

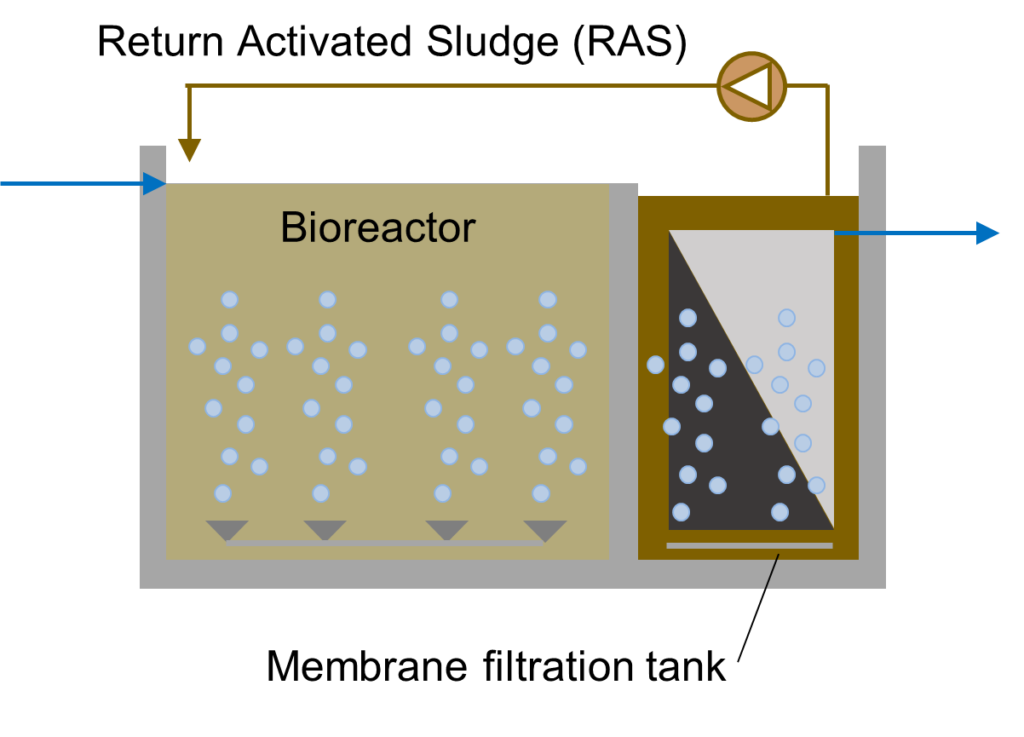

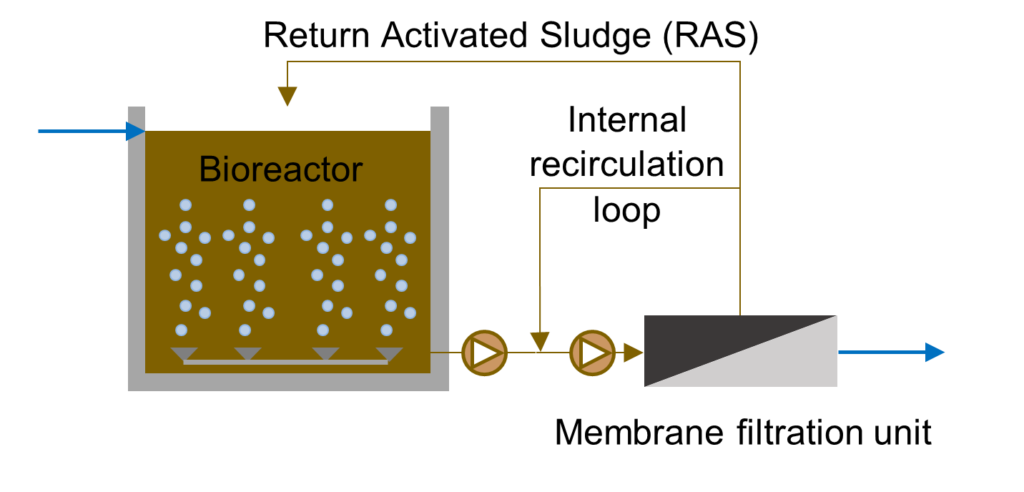

Two process configurations are possible:

- Submerged MBR, in case vacuum-driven membranes are used (like PCI HF-Zmbr2 Series);

- Sidestream (or external) MBR, in case pressure-driven membranes are used (like PCI A-Series).

Usually, pressure-driven membranes are used for smaller installations and/or tough-to-treat industrial wastewaters, while submerged membranes are used for medium and large installations.

What are the advantages of membrane bioreactors (MBR)?

1) Smaller footprint (new WWTPs) or higher hydraulic throughput (existing WWTPs)

Large clarifiers no longer are needed. A smaller often rectangular shaped chamber, fitted with the membrane cassettes replaces the secondary clarifier whose size is governed by hydraulic and solids loading. On top, because of the higher biomass concentrations that can be sustained within the bioreactors, the same total mass of solids is stored in a smaller tank, resulting in up to 50% smaller footprint.

2) High-quality effluent, free of bacteria and pathogens

In comparison to the activated sludge (CAS) process, the effluent is free of suspended solids and reduced bacteria and viral content. Therefore, minimum disinfection is required.

Therefore, the MBR process easily allows the treated effluent to be discharged to sensitive receiving bodies or to be reclaimed for applications such as urban irrigation, utilities or toilet flushing. Meanwhile, it is also of high quality for feeding directly to a reverse osmosis (RO) process.

This is becoming increasingly crucial in the view of the strict effluent quality requirements imposed by local regulations taking effect during the recent years and in the near future.

3) Higher automation capabilities

The operation of the MBR system can be fully automated, minimising operators intervention that are typically required for conventional treatment plants. This means that the MBR process can be easily implemented also in decentralized sites.

How can we help you?

Do not hesitate to contact our experts who will work with you to conduct project assessments, run a pilot test, customise, design and install your membrane filtration system, which best fits your needs.

Applications of membrane bioreactors (MBR)

Currently, MBR technology is widely used for the treatment of various types of wastewater streams, such as municipal wastewater treatment, industrial wastewater treatment and landfill leachate.

1) Municipal wastewater treatment

MBR systems were originally developed for municipal wastewater treatment applications, with a focus on water reuse and recycling. The MBR is an ideal process for recycling municipal wastewater in water and space limited locations because of its compact size, its ability to produce reusable water, and trouble-free operation.

2) Industrial wastewater treatment

Industrial waste streams may include high organic loadings and chemical substances that are particularly difficult to handle or degrade, making alternative treatment like MBR more desirable.

In fact, MBRs completely retain the biomass and this enables a higher biodiversity of the bacteria and protozoa population, favoring the biodegradation of recalcitrant substances (such as herbicides, pesticides, etc.).

3) Landfill leachate treatment

In addition to municipal and industrial wastewater treatment, MBRs have been utilised in a number of other areas. The treatment of landfill leachates is an example. Landfill leachates usually contain high concentrations of organic and inorganic compounds. MBR systems have been successfully used with additional treatment steps for inorganics and heavy metal removal, such as nanofiltration and reverse osmosis processes.

Our MBR solutions

PCI Membranes can supply a number of technologically advanced and economical membrane geometries/configurations that will suit all your requirements.

MBR Systems can be provided either as standard packages or bespoke designs to suit the nature of the wastewater and existing site infrastructure.

The produced effluent can also be subjected to a further polishing step with the use of PCI Membranes’ range of reverse osmosis membranes to produce a filtrate stream with the highest quality.

1) Our tubular membrane for side-stream MBRs: A8 Series

PCI Membranes’ A8 Series is a tubular membrane module equipped with 8-mm tubes made of PVDF and 100k or 200 kDa MWCO (other selectivities are available at request). It has 8” (DN200) diameter and 3 or 4 m length, with respectively 27 and 36 m2 membrane area. The housing (or module shroud) is made of GRP, thus having better chemical resistance to chlorine and strong acids as well as being lighter to handle.

The module comprises of two main parts, the membrane core and the shroud. The core is fixed into the shroud; end seals prevent leakage of feed and concentrate from the module, while the inner O-Rings prevent leakage of permeate. Modules are usually connected in series with U-bends.

2) Our hollow fibre membrane for submerged MBRs: PCI-HF-Zmbr2 Series

PCI-HF-Zmbr2 Series is a hollow fibre membrane cassette equipped with PVDF membranes having a pore size of 0.02 µm.

Cassettes are made of membrane modules, which are available in 2 different heights, 1,948 (S type) and 2,448 mm (U type). Two sizes of cassettes exist, one up to 12 modules and the other up to 40 modules: in case of S type modules, this means up to 480 m2 (12 modules, S12) and 1,600 m2 (40 modules, S40) while, in case of U type modules, this means up to 624 m2 (12 modules, U12) and 2,080 m2 (40 modules, U40).

Launched in 2022, our second-generation membrane cassette sport even higher membrane packing density (+10%) and lower scouring energy consumption (-5%) than our first-generation products.

Summary

MBR is the low-footprint, high-effluent-quality solution to your wastewater treatment needs. It can be used to upgrade existing WWTPs as well as to build new, state-of-the-art facilities.

As one of the few suppliers offering both submerged and sidestream membranes, we are glad to support you! Our experts will help you to find the MBR solution which is the most suitable to your specific case.