Hollow Fibre Membrane Cassettes

PCI Membranes’ Hollow Fibre Series is the membrane solution for high turbidity, large capacity membrane plants

PCI Membranes’ submerged hollow fibre is specifically designed for high turbidity and large installations, such as:

• Wastewater treatment (MBR process);

• Drinking water (backwash water recycle).

The resulting permeate is low in turbidity (< 2 mg SS/L and < 0.5 NTU) and fouling potential (SDI < 3) and is suitable to fed to spiral-wound nanofiltration (NF) or reverse osmosis (RO) membranes, like PCI Membranes’ SpiraCore elements.

Hollow Fibre Series Benefits

- Lowest whole-life cost MBR solution

- Consistently high quality, partially disinfected effluent suitable for reuse or direct discharge

- Intensive process enabling minimal footprint requirements

- Low operation and maintenance requirements as it is highly suited to automation

- Capable of biological nutrient removal

- Modular design providing process flexibility

- Multiple, tailored cleaning techniques can be used to maximise performance according to the specific effluent’s characteristics

The MBR Process

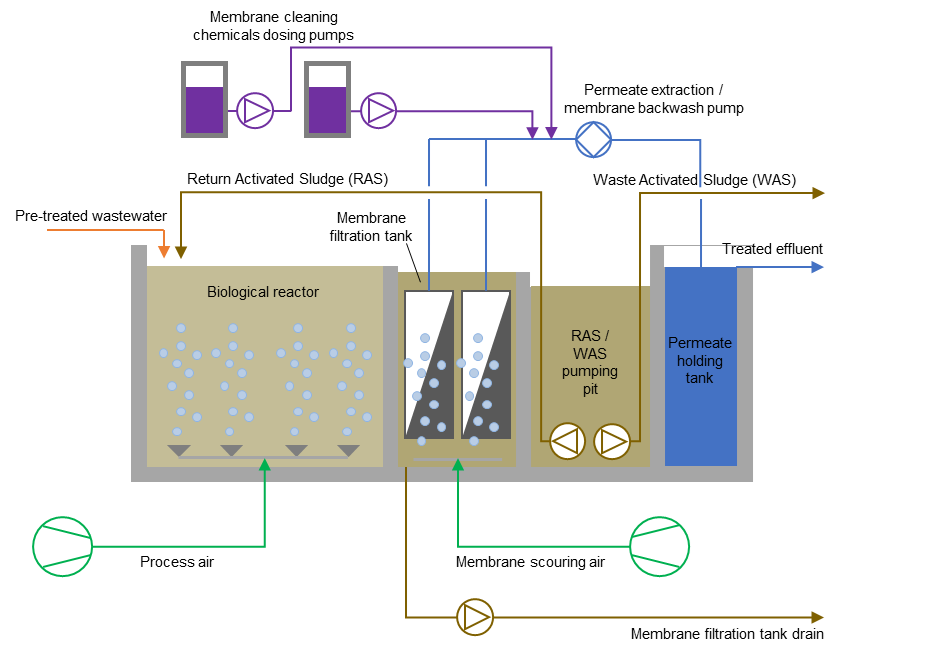

The Membrane Biological Reactor (MBR) process is an intensive treatment technology which combines the biological treatment stage (removing biodegradable substances) with the membrane filtration stage (removing the biomass from the treated wastewater). This makes the system very robust and surprisingly simple to operate, enabling the treatment process to tolerate considerable fluctuations in influent quality.

Following is a presentation of a typical submerged MBR process layout (pump-from with external filtration tank):

As a result, a high quality of effluent is produced that is suitable for on-site reuse or direct discharge. If required, the MBR process is also highly suited to be combined with a polishing process, such as PCI Membranes’ range of spiral-wound Nanofiltration and Reverse Osmosis membranes, which can purify water to almost any standard required.

MBR systems can be provided either as standard packages or bespoke designs to suit the nature of the wastewater to be treated and integration into the existing site infrastructure.Additional information about the MBR process can be found in the dedicated article.

Backwash Water Recycle

In drinking water applications, PCI Membranes’ HF Series can be used to recycle backwash water coming from other processes, such as multimedia filters and membrane filtration units. This is possible thanks to the high tolerance to suspended solids.

By installing a relatively submerged small hollow fibre unit, you can sensibly increase the overall recovery rate of your potable water treatment process, reducing both unit operating costs and environmental impact. This does not require any notable intervention on existing process units.

Features of PCI Membranes’ MBR Solution

The unique design of PCI Membranes’ hollow fibre membranes incorporates braiding to significantly improve their ability to withstand the harsh operating environment in which they are immersed, thus increasing their lifespan.

Each of the membrane fibres is connected to a permeate collection device on the top end, and to the aeration device on the bottom end, so that mechanical stress on the fibre is minimized. Each assembly of fibres, permeate collection device and aeration device is termed “module” and provides the optimal degree of restraint and system robustness.

Several modules are installed within a stainless steel frame (termed “cassette”), which incorporates manifolds for permeate extraction and aeration, thus minimizing the number of connection points required to install the membrane filtration system.

| Parameter | Unit | Value |

| Membrane geometry | – | Hollow fiber (reinforced) |

| Membrane material | – | PVDF |

| Membrane fibre diameter | mm | 1.0 mm (ID) / 2.0 mm (OD) |

| Membrane nominal pore size | µm | 1.0 mm (ID) / 2.0 mm (OD) |

| Filtration direction | – | Out-to-in |

| Operating temperature range | °C | 5 to 45 |

| Maximum operating pressure | bar | -0.6 (during filtration), +1.0 (during backwash) |

| pH range | – | 1 to 12 |

| Cassette frame material | – | Stainless Steel AISI 316L * |

Advanced Cleaning Techniques

The high concentration of contaminants within the membrane filtration tank creates a challenging environment for efficient membrane filtration. Therefore, PCI Membranes’ HF Series incorporates various cleaning techniques to minimise the build-up of material upon the membrane surfaces, maintaining optimum filtration performance. This reduces operating costs and the need for aggressive chemical cleaning of the membranes, thus extending their life.

Additionally, our hollow fibre membrane sport exceptional chemical resistance, enabling as well long membrane life:

Chemical Cleaning Resistance

• Sodium Hypochlorite:

• Typical: 500 to 1,500 ppm at ≤ 40°C

• Maximum: 5,000 ppm

• Cumulative exposure: 2,880,000 ppm x hour

• Hydrochloric Acid:

• Typical: 2,000 ppm at ≤ 40°C

• Maximum: 30,000 ppm

• Cumulative exposure: 1,440,000 ppm x hour

• Citric Acid:

• Typical: 5,000 ppm at ≤ 40°C

• Maximum: 15,000 ppm

• Cumulative exposure: 1,440,000 ppm x hour

Data Sheets

How can we help you?

If you need further information regarding our hollow fibre solutions, do not hesitate to contact our experts.