Fruit Juice Clarification with Membranes

Introduction

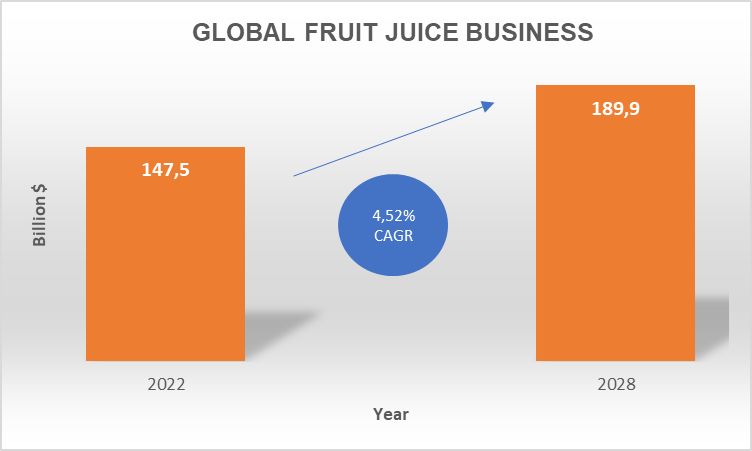

According to the Fruit Juice Market Report, in 2022 global fruit juice business size has grown to 147.5 billion dollars and is going to expand in the following years reaching almost 190 billion dollars by 2028 [1].

It is driven by campaigns promoting healthy lifestyle going together with increasing consciousness of people, which more often choose valuable and nutritious beverages instead of soft drinks with a high sugar and caffeine content. Recent research shows that a significant increase in fruit juice consumption was noticed during and after COVID-19 pandemic [2-4] in order to supplement vitamin C and support the immune system. Consumers that are increasingly concerned about diet choose fruit juices because they naturally contain beneficial health nutrients, such as minerals, vitamins, dietary fiber and antioxidants.

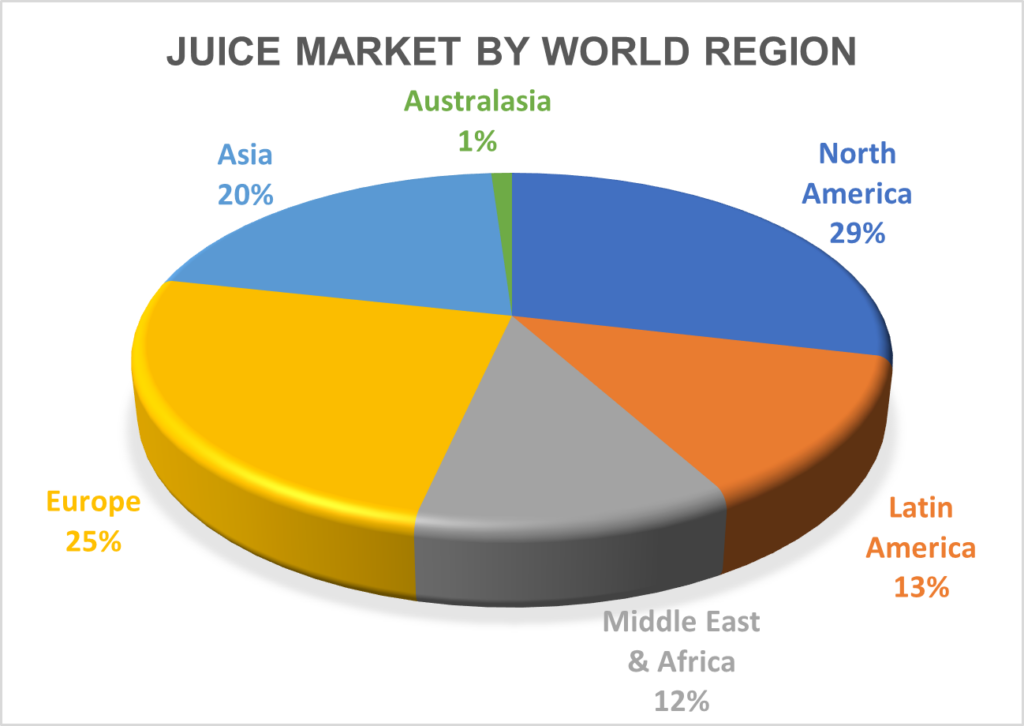

The biggest part in the global market in terms of revenue is North America. Although Europe and Asia’s market is bigger, Latin America is showing the biggest potential in business growth in the following next years.

Fruit juice production traditionally was performed with the use of thermal treatment, to avoid microorganisms’ growth and thus extend a product’s shelf-life. Concentration by evaporation was traditionally applied to minimizing juice volume by water evaporation to reduce storage space and facilitating transportation by lowering its costs. The main drawback of this technology, besides its high energy consumption, is the fact that by heating up the fruit the majority of the active substances such as vitamins, phenolic compounds, anthocyanins, carotenoids or even aroma are lost, due to its instability and degradation at elevated temperatures [5,6].

Why Juice Clarification is important?

The clarification process is considered as one of the most important stages in fruit juice processing for industrial production. The purpose of this treatment is to remove as many as possible components that causes turbidity, such as pectin’s, cellulose, starch, proteins and metals. Removing these substances significantly improves the purity of the juice and reduces the juice’s viscosity, which results in positive effects on its appearance and flavor.

Clarification can be performed by a mechanical, chemical and/or enzymatic process. Membrane treatment is an efficient, cost-effective and low-temperature mechanical separation process widely used for juice clarification purposes.

Benefits of Juice Clarification with Membranes

Because membrane technology requires less labor, has lower operating costs and operates at low temperatures, it has replaced conventional juice clarifying and concentration procedures. It almost completely preserves the juice’s nutritive, organoleptic and sensory qualities.

Membrane techniques for juice clarification have a number of advantages over conventional processes, including lower heat product damage, increased aroma and colour retention, lower energy use and lower equipment costs.

How can we help you?

Do not hesitate to contact our experts who will work with you to conduct project assessments, run a pilot test, customise, design and install your membrane filtration system, which best fits your needs.

Step-by-step juice clarification process using membranes

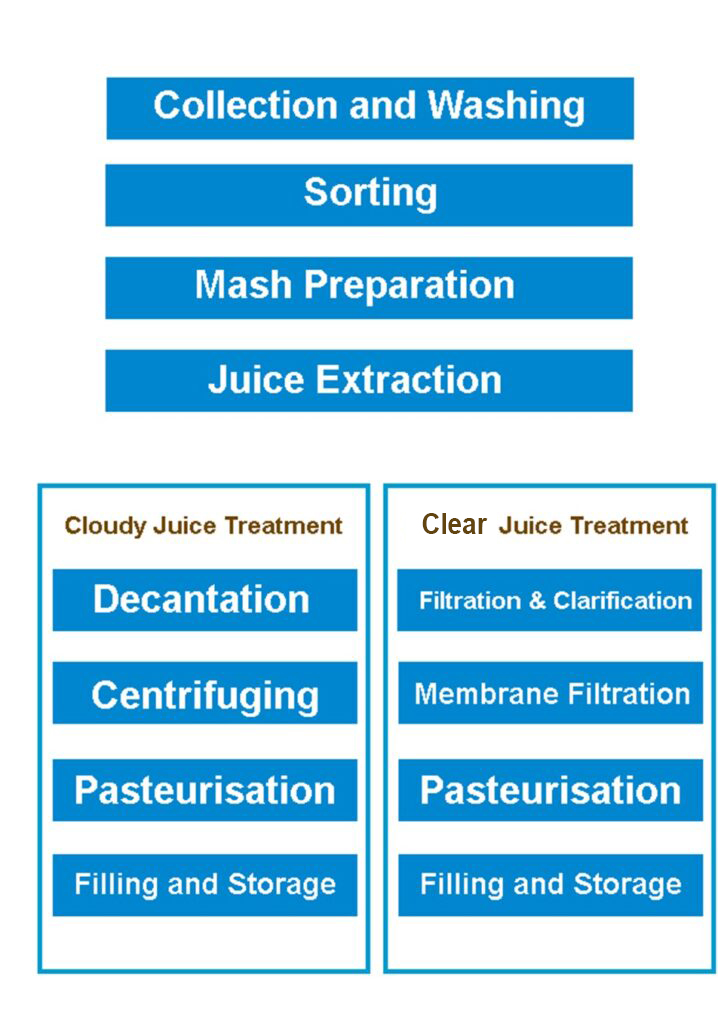

Before the juice is produced, fruits are subjected to several processes. After collection, fruits are washed from contamination like dirt, stones, leaves, etc. and sorted according to size. The next step is the mash preparation, which may include pitting, mincing or crushing. Afterwards comes juice extraction, usually performed by pressing or squeezing, followed by decantation. The type of juice extraction depends also on the type of fruit that is being processed. From this moment, the further treatment varies with the type of final product that is required. Cloudy juice production requires less treatment and results in obtaining products with pectin, cellulose, tannins, pulp and fibres. Usually, treatment is limited only to centrifuging and removing the biggest solid parts. After pasteurization, performed to destroy microorganisms in juice, comes the last step, which is filling and storage [7].

When it comes to clear juices, after extraction by pressing, the resulting liquid fraction undergo filtration and clarification. Traditionally, in order to obtain satisfactory results, several steps were performed: centrifuging (the same as in cloudy juice production process), then enzymatic treatment for removal of pectin and several filtration steps to remove the remaining colloids [7]. Because of the above-mentioned, alternative technologies are implemented in order to shorten production time and simplify the production process. After the necessary step of depectinization, an enzymatic pretreatment which is applied to decompose pectin’s and starch and optimize the mash viscosity, membrane technology has been found to be an advantageous technique that efficiently helps to overcome the drawbacks of conventional procedures. Membrane filtration is a low-cost technique with minimal footprint requirement, so that it is an attractive choice for industrial applications [5,8]. Polymeric tubular membranes operate at low temperatures and thanks to that preserve the required quality of the final product, providing juices with good sensorial characteristics and nutritive content which is a crucial goal for the juice industry. It is a simple mechanical process, which does not implement any thermal or chemical treatment and, thus, greatly simplifies the process operation and the obtained product has good quality and may be produced in higher yield.

The most advantageous type of membranes for this application is tubular configuration. Thanks to its cylindrical shape and open channel design, it is the most suitable for high-solids and viscous liquids such as freshly extracted fruit juices. Crossflow operation helps to reduce fouling issues and ensures high filtration efficiency and yield. Broad spectrum of filtration accuracy and high thermal, mechanical and chemical stability result in long membrane life, providing a reliable solution for the juice industry to produce healthy and tasty beverages.

Methods commonly applied for clarification of juices are microfiltration (MF) and ultrafiltration (UF).

Microfiltration membranes characterized by the largest pore size (0.1 µm or larger) can be used in case of dark-coloured juices, that by their nature possess more fouling compounds such as large particles, polyphenols, pectins and tannins. Light-coloured juices often are successfully clarified with the use of ultrafiltration, whose molecular weight cut-off (MWCO) is around 100-200 kDa. Ultrafiltration allows efficient removal of microorganisms, proteins, suspended colloids, polyphenolic compounds, starch and pectin, and improves the clarity and texture of the juice.

Compared with traditional technologies, MF/UF juice clarification ensures higher yields, typically 94% or more. Diafiltration is often used to further increase the yield up to 99%. The achievable yield depends both on the fruit to be processed (i.e., on its pulp content) and on the operating parameters.

Our solutions for juice clarification

Our membrane products are designed to provide the most effective juice clarification process for a large variety of juice types.

They are ideal for:

- Light juices such as apple, pear, peach, pineapple, orange, lemon and light grapes;

- Pink juices such as pomegranate, and strawberry;

- Dark juices such as cherry, carrot, blackberry, beetroot and dark grapes.

The typical MF and UF membranes used to clarify these juices are made of FDA- and EU-approved materials.

A Series

Our MF and UF tubular membranes used in fruit juices applications are made from PVDF. We recommend using either the A19 or A37 modules, which are comprised of a robust Stainless-steel housing and a replaceable, potted core of 19 or 37 membrane tubes, respectively. The open channel design of the A19 and A37 modules enables them to treat liquids with high suspended solids, without plugging and ensuring a highly effective CIP process. Our unique in-situ replaceable core feature enables fast, easy and cost-effective remembraning operations. A summary of the main membranes used for juice clarification is shown below.

| Membrane | Specification | Nominal retention character |

| FPA10 or FPS10 | Ultrafiltration | 100 kDa |

| FPA20 or FPS20 | Ultrafiltration | 200 kDa |

| LPA450 or LPS450 | Ultrafiltration | 450 kDa |

| LMA02 or LMS02 | Microfiltration | 0.2 µm |

For apple juices only, we recommend using our FPA10 or FPS10 tubular UF membranes with a MWCO (Molecular Weight Cut-Off) of 100 kDa. This will help to achieve very light colour of clarified apple juice while maintaining a good quality product, with low turbidity up to a maximum of 0.5 NTU.

The most common UF membrane used in juice applications has a MWCO of 200 kDa. When processing light juices, we recommend using our FPA20 or FPS20 tubular ultrafiltration membranes.

For flexibility, when running both light and pink juices, LPA450 or LPS450 tubular UF membranes with a MWCO of 400-500 kDa can be used. These membranes offer greater performance with a minimum pressure drop, while maintaining the organoleptic characteristics of the juices.

For dark juices, we recommend using our LMA02 or LMS02 tubular MF membranes with a nominal pore size of 0.2 µm. They have a more opened membrane surface compared to the LPA450 and LPS450 membranes. This will help keep the colour while maintaining a good quality product, with low turbidity up to a maximum of 1 NTU.

As to membrane selection, detailed guidelines are summarized below.

| Juice Classification | Membrane Type | Advantages | Membrane Type |

| Light: Apple only | FPA10 or FPS10 | High quality product and low turbidity maximum of 0.5 NTU | Only recommended for apple juice |

| Llight | FPA20 or FPS20 | High quality product and turbidity lower than 1 NTU | |

| Light and/or Pink | LPA450 or LPS450 | High quality product and turbidity lower than 1 NTU | It offers flexibility in terms of production scheduling when using different types of juices |

| Dark | LMA02 or LMS02 | High quality product and low turbidity maximum of 1 NTU |

For some juice applications, it maybe possible to use powder activated carbon (PAC) with the filtration process to further enhance /reduce the juice turbidity (NTU).

Application of PAC during the juice filtration is customer’s or market specific and the recommended permissible concentration and type, by PCI is between 0.6 – 1 g/l of Norit Ca1/Darco KBB/Aktikol FA UF. The use of PAC to further improve the juice NTU constitute some risk for the membranes, and it is therefore limited. Please contact PCI Membranes to learn more.

Bibliography

- Fruit Juice Market Size, Share, Trends & Forecast 2023-2028 (imarcgroup.com)

- Marty, L.; de Lauzon-Guillain, B.; Labesse, M.; Nicklaus, S. Food choice motives and the nutritional quality of diet during the COVID-19 lockdown in France. Appetite 2021, 157, 105005.

- Bracale, R.; Vaccaro, C.M. Changes in food choice following restrictive measures due to COVID-19. Nutr. Metab. Cardiovasc. Dis. 2020, 30, 1423–1426.

- Heng, Yan, Marisa Zansler, and Lisa House. “Orange Juice Consumers Response to the COVID-19 Outbreak: FE1082, 06/2020.” EDIS 2020.4 (2020): 4-4.

- Bhattacharjee, Chiranjit, V. K. Saxena, and Suman Dutta. “Fruit juice processing using membrane technology: A review.” Innovative Food Science & Emerging Technologies 43 (2017): 136-153.

- Ağçam, Erdal, Asiye Akyıldız, and Burcu Dündar. “Thermal pasteurization and microbial inactivation of fruit juices.” Fruit juices. Academic Press, 2018. 309-339.

- Sarbatly, Rosalam, Jamilah Sariau, and Duduku Krishnaiah. “Recent Developments of Membrane Technology in the Clarification and Concentration of Fruit Juices.” Food Engineering Reviews (2023): 1-18.

- Charcosset, Catherine. “Classical and recent applications of membrane processes in the food industry.” Food Engineering Reviews 13.2 (2021): 322-343.