Milk Standardisation – Membrane solutions for dairy products

Standardisation

Standardisation refers to the process of adjusting the fat, protein, solids and non-fat content of milk and cream to standardise values, depending on the type of end-product being produced. This is mainly done to maximise the economic return from milk components whilst maintaining both the end-product quality and composition.

The standardised fat content of these dairy products, i.e. cheese, usually ranges between 0.5% to a maximum of 3.5%. What’s more, the protein amount of milk collected by dairy plants varies by season due to a variety of factors including: stage of lactation, weather, feeding and breed of lactating cows. This issue is eliminated by milk protein standardisation.

Possible Applications for Milk Standardisation

• Milk and milk cream,

• Cheese milk,

• Yogurt production,

• Fermented dairy products,

• Milk powder production, and

• Other dairy products.

PCI Membranes’ Solutions for Milk Standardisation

PCI Membranes offers a number of technologically advanced and economical membrane geometries/configurations that will satisfy all your requirements.

The objective is to standardise the protein, total solids and other components to a desired level during production. The membrane selection will depend on your specific application type and targets. In particular, we recommend using either our spiral-wound or tubular membranes for milk standardisation and similar dairy applications.

Membrane filtration gives:

• A permeate containing water, salts and lactose;

• A concentrate containing valuable proteins, including those of the whey loss during the cheese production.

At the same time, we offer all the membrane filtration range: microfiltration, ultrafiltration, nanofiltration, and reverse osmosis.

How can we help you?

Do not hesitate to contact our experts who will work with you to conduct project assessments, run a pilot test, customise, design and install your membrane filtration system, which best fits your needs.

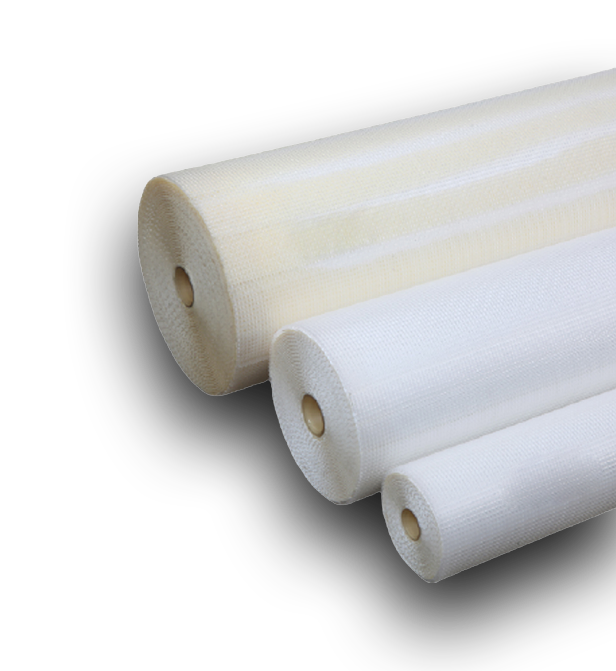

1) Our spiral-wound membrane elements for dairy applications

Our spiral-wound dairy elements are made with highly efficient membranes for ultrafiltration (UF), representing a great quality and cost-effective alternative to other membrane suppliers. Extensive field trials show that the protein loss in permeate with the spiral dairy ultrafiltration (UF) membranes is extremely low compared to competitors’ membranes. Therefore, using our spiral dairy ultrafiltration (UF) membranes will increase the protein yield and thus the overall profitability of the plant.

Main characteristic of our spiral-wound dairy ultrafiltration (UF) elements:

• MWCO: 5,000 and 10,000 Da with PP or PET non-woven;

• Uniform pore size distribution and high porosity;

• Almost 100% whey protein retention;

• Excellent separation between whey protein and lactose (as lactose won’t be retained);

• Ability to tolerate high temperature (up to 75°C for membrane with PP non-woven) during both operation and cleaning;

• Ability to withstand chlorine cleaning (200 ppm Cl2 at pH 10.5 or higher);

• Operation and cleaning pH range of 1 to 13 (for PP non-woven);

• High fouling resistance and ease of cleaning.

We also recommend using our spiral membranes for the pre-concentration steps of milk protein.

Shall we add a link to the SpiraCore for dairy applications?

2) Our tubular membrane elements for dairy applications

PCI Membranes also provides tubular membrane elements. With our unique product range, we enable our customers with additional dairy applications compared to spiral-wound membranes.

Benefits of our dairy membrane solutions

– Standardise protein, solids and other components to the desired level;

– Improve production yield and product consistency, with increased product shelf-life;

– Reduction of production time. In fact, protein pre-concentration is accomplished to improve curd formation.

At PCI Membranes, we are very glad to solve your problems with our solutions! Our experts will help you to find the dairy membrane solution which is the most suitable to your specific application.

At PCI Membranes , we provide the dairy industry with membranes and optimised solutions for your process, water and wastewater needs.