Advanced Filtration Solutions for the Oleochemical Industry

Delivering cleaner products, safer operations, and lower costs.

At PCI Membranes® and Amafilter®, we help oleochemical producers achieve high-purity products, maximize uptime, and reduce operating costs through proven, automated filtration and membrane separation systems. Our technologies efficiently remove solids, soaps, and trace metals from feedstocks and process fluids — protecting critical equipment, preventing corrosion, and ensuring consistent product clarity and quality across your production line.

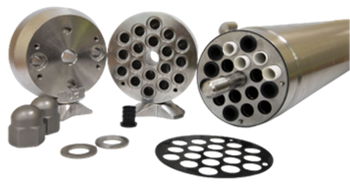

Amafilter®’s Cricketfilter® Automated System — Advanced Filtration for Oleochemicals

The Amafilter® Cricketfilter® system sets the industry benchmark for automated solids removal in oleochemical production. Designed for efficiency, safety, and minimal operator intervention, the fully enclosed system reduces maintenance, increases throughput, and ensures consistent, repeatable product quality.

Key Advantages

• Up to 40% more filtration area and 40% higher cake capacity than traditional round elements.

• 30% faster batch times compared to conventional filter presses.

• >90% fewer maintenance interventions, typically only once per year.

• Closed, automated operation for safer, cleaner, and more sustainable processes.

• Superior particle removal delivering premium product clarity and higher yields.

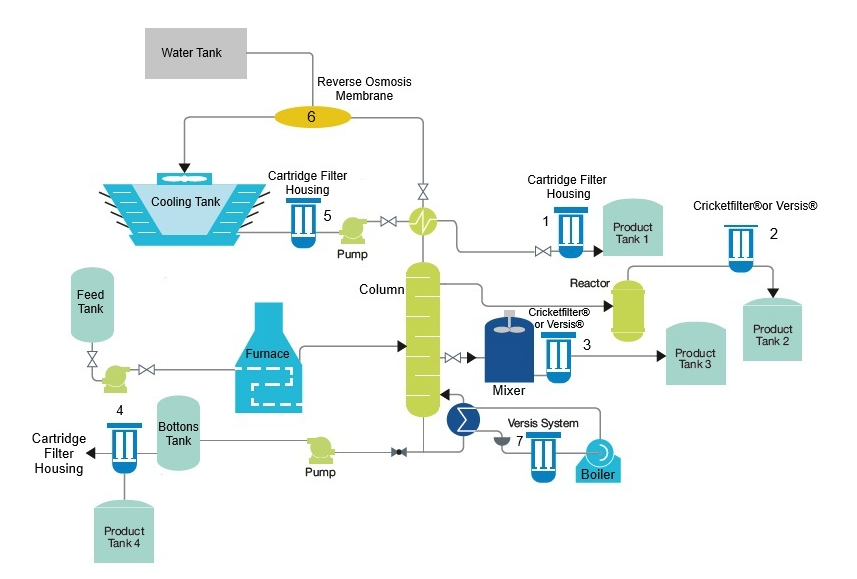

Filtration and Membrane Solutions for Every Stage of Oleochemical Production

| SOLUTION | APPLICATION | CUSTOMER BENEFITS |

|---|---|---|

| Cartridge Filter Housings | Prevention of fouling building-up. | Prevents scale build-up resulting in less flow restrictions and outing maintenance by up to 30%. |

| Cricketfilter®Automated System | Removal of solids added or formed in reactors and mixers. | Automated solids removal with up to 40% more capacity – reduced downtime and labour. |

| Versis® Pressure Leaf Filter System | Removal of bleaching earth after the reactor or mixer. | Proven, robust design ensure consistent quality and optimized process performance. |

| Cartridge Filter Housings | Utility and polishing filtration – protects pumps, heat exchangers, and cooling systems. | Prevents fouling and scale build-up, reducing maintenance by up to 30% |

| Reverse Osmosis Membranes | Purifies condensate from evaporation/distillation for reuse. | >90% revovery rate – reduced freshwater consumption and waste disposal costs. |

| SPARE PARTS | FEATURE | CUSTOMER BENEFITS |

|---|---|---|

| Cricketfilter® Cloths | Chemical-resistant or food-grade materials. | Replace only once a year – reduced spare parts costs and downtime. |

| Drain and Top Cloths | Handle a wide range of liquids and temperatures. | Maximised flux capacity and extended service life. |

| Pressure Filter Leaves (Verisis® System) | Replaceable or -re-screened. | Immediate efficiency improvements and sustainable reuseof softened water. |

Versis Vertical Pressure Filter System

Amafilter®

Amafilter®

PCI Membranes®

Amafilter®

Complete Filtration Expertise

With PCI Membranes® and Amafilter® , you gain more than just equipment — you gain a trusted process partner.

Our support extends from laboratory testing and pilot trials to full-scale system optimization and service support, helping you maintain peak performance and product consistency across all oleochemical processes.

Why choose PCI Membranes® and Amafilter® for Oleochemicals?

- Proven success with leading oleochemical producers worldwide.

- Decades of experience in solid-liquid separation and membrane technology.

- Fully integrated filtration and membrane solutions for end-to-end process efficiency.

- Sustainable technologies that reduce waste, minimize energy use, and enhance safety.

PCI Membranes® and Amafilter® — Cleaner. Safer. More Efficient.

Empowering the oleochemical industry with innovative filtration and membrane technologies designed for performance, purity, and reliability.