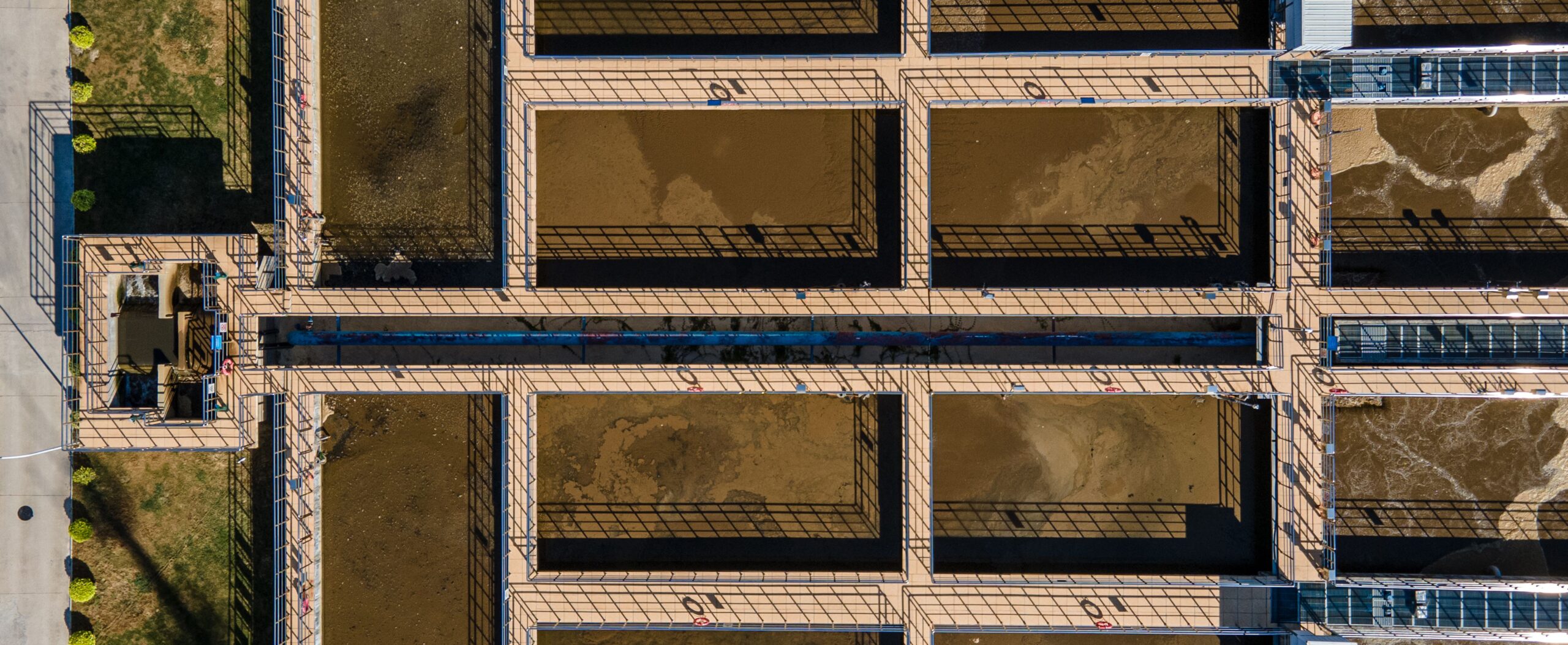

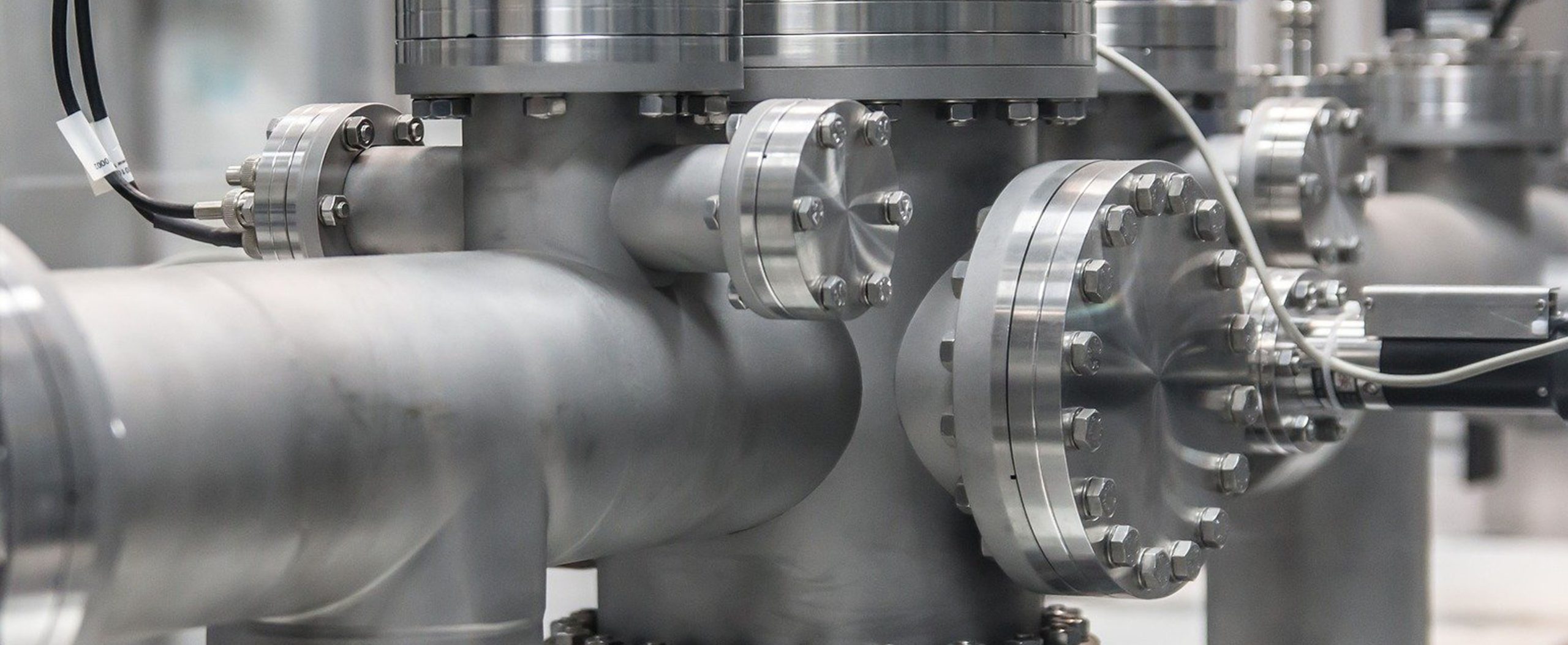

Design data Below are listed the most important parameters that are required to properly design an MBR (Membrane Biological Reactor) system: Feed quantity: Average Daily Flow (ADF); Peak Hourly Flow (PHF); Feed quality: Non-ionic: Total Suspended Solids (TSS), Volatile Suspended Solids (VSS), 5-days Biological Oxygen Demand (BOD5), Chemical Oxygen Demand (COD), Organic Nitrogen, Total Phosphorous […]

View More

Standardisation Standardisation refers to the process of adjusting the fat, protein, solids and non-fat content of milk and cream to standardise values, depending on the type of end-product being produced. This is mainly done to maximise the economic return from milk components whilst maintaining both the end-product quality and composition. The standardised fat content of […]

View More

Executive summary What is a membrane bioreactor? A Membrane BioReactor (MBR) is a process which combines a microfiltration or ultrafiltration membrane unit with a suspended growth bioreactor, and is now widely used in both municipal and industrial WasteWater Treatment Plants (WWTPs). 1) Bioreactor: In a wastewater treatment process, a bioreactor is specifically-designed chamber to support […]

View More

What is potable water? Potable water is water which is safe to drink. It must be safe in terms of chemical composition and organoleptic properties. Usually, potable water comes from surface or underground water, which will then need be treated to levels that meet the local standards for consumptions. Access to safe potable water is […]

View More

BACKGROUND PCI Membranes was contacted by a multinational consumer goods company that specialises in producing a wide range of hygiene and personal care products, to evaluate the feasibility of using a tubular membrane system for the treatment of a laundry detergent wash-water resulting from one of their global manufacturing sites, with a target to concentrate […]

View More

THE CHALLENGE Due to the nature of leachate and more stringent environmental legislation that prohibits the discharge of this wastewater into a sewer network or nearby river/lake, a waste treatment company located in a Scandinavian region has decided to explore the most suitable treatment options available on the market. Therefore, the reason to opt for […]

View More

COMPANY OVERVIEW AND APPLICATION Our customer specialises in processing potatoes for the purpose of manufacturing products such as: potato starch, crystalline and anhydrous glucose, glucose syrups, potato flakes or potato protein for feedstuff purposes. The main objective of the client is to concentrate and recover as much protein and potassium resulting from a protein decanting […]

View More

INTRODUCTION Stora Nymölla AB is one of the world’s largest manufacturers of bleached magnifite pulp. Production of pulp started in 1962 at Nymölla, and actual paper manufacture began in 1972. At present, the mill’s capacity is 300,000 tonnes per year, of which 200,000 tonnes is used by Stora Nymölla for the manufacture of high quality printing […]

View More

INTRODUCTION Achnasheen is a village community of 120 people in Wester Ross, 40 miles North of Inverness in the Highlands of Scotland. Water from the Achnasheen burn has traditionally been filtered and chlorinated before being supplied to the village. The existing treatment process has consistently failed to meet Scottish Water’s drinking water quality standards due […]

View More

BACKGROUND ARP has expanded continuously since 1958 whe 7000 tonnes of tomatoes were processed, up to 100,000 tonnes/year (1984 figures). The factory produces 28º-30º Brix and 36º-38º Brix concentrate for major European clients. PREVIOUS PROCESS In the 1983 season the factory process was the standard hot break process with feed juice at an average of […]

View More