The Fyne Process

Tubular Membranes

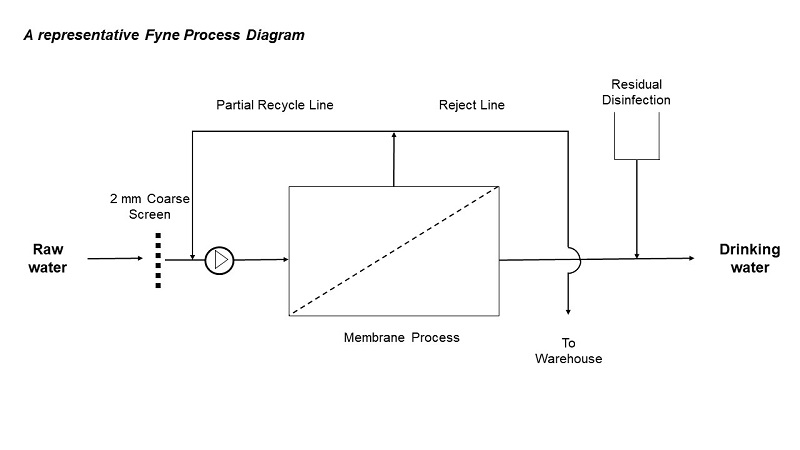

PCI Membranes’ own 12mm diameter tubular membranes are used in the Fyne process due to their ability to handle suspended solids without blocking of membrane pores. The Nano-Filtration (NF) membranes retain contaminants on the raw water side and allow potable water to permeate. The deposition of impurities upon the membrane’s surface is minimised by maintaining a high crossflow velocity using a partial re-cycle flow, thereby sustaining high filtration efficiencies. As the process’ waste stream is simply concentrated raw water, there are no environmental concerns to prevent local water course disposal.

No Coagulants

Conventional treatment processes remove fine particles (such as colour and pathogens) using chemical coagulants, which have various drawbacks, including the following:

- Health and safety concerns for operational staff and the environment.

- Transportation issues and specialist on-site handling and storage requirements

- Production of chemical bearing sludge, requiring costly removal, re-processing and disposal

- Delayed response to changes in raw water quality, causing a risk of substandard

- quality water being supplied

The Fyne process does not require coagulants as the membranes operate at a molecular level, hence the process does not generate sludge and is impervious to both sudden and substantial changes in raw water quality.

Membrane Cleaning

The membranes are routinely cleaned using a mechanical pigging technique employing natural foam rubber balls. After a predetermined operational time period the plant’s flow direction is automatically reversed, causing the balls to be squeezed along the length of the membrane tubes, thus scouring accumulated deposits from the filtration surface. The removed deposits are gradually disposed of via the waste stream to the local water course. This unique feature makes the Fyne process more environmentally sensitive than all conventional treatment alternatives.

References and Reliabilty

Since its development in 1992, over 40 Fyne process plants have been installed across the world, principally in Scotland, Ireland, Canada and the USA. The process has been verified under the US Environmental Protection Agency’s `Environmental Technology Verification’ program, and approved by the UK’s Drinking Water Inspectorate. The proven performance of the Fyne process over extended time periods gives Aquious – PCI Membranes confidence in offering guarantees for both production capacity and water quality.

Applications

The Fyne process provides a filtration barrier to the following contaminants (amongst others):

- Organic carbon – the principal pre-cursor material leading to the formation of regulated disinfection by- products (e.g. carcinogenic THMs).

- All regulated pathogens, including bacteria, protozoan cysts (e.g. Cryptosporidium) and viruses.

- Numerous metals, including iron, aluminium and manganese.

- Turbidity, suspended solids and algae.

The Fyne process is a market leading technology for the treatment of poor quality, variable water sources, particularly those containing carbonaceous organic colour (humic and fulvic acids), which are common in peat rich areas. The Fyne process has repeatedly been proven to provide the lowest capital and operating costs (and hence whole life costs) for small to medium sized systems, with installed plants having capacities ranging from 5ml/day to 1420ml/day.

Package Membrane Plants

PCI Membranes has recently introduced Package Membrane Plants (PMP’s) for the Fyne process, which offer the following features:

- Reduced costs and delivery times

- Minimal footprint

- Performance testing prior to shipping – minimising on-site commissioning

- Supplied in transportable buildings available in a wide range of designs and finishes to meet specific requirements (e.g. planning approval)

- Single phase electrical supplies can be used as a power source for smaller sites, easing installation in remote locations

As the PMP’s are supplied as complete treatment processes incorporating all the necessary peripheral items, they simply require positioning and connection to services upon arrival on site before final performance validation is commenced. Full instrumentation and automation can be incorporated to enable unattended monitoring and operation.